How To Produce Barite Powder-CLIRIK Barite Powder Grinding Mill

How To Produce Barite Powder?This article will help you understand the production process of barite powder : Crushing,Screening and Grinding.

Barite crushing and screening and grinding process:

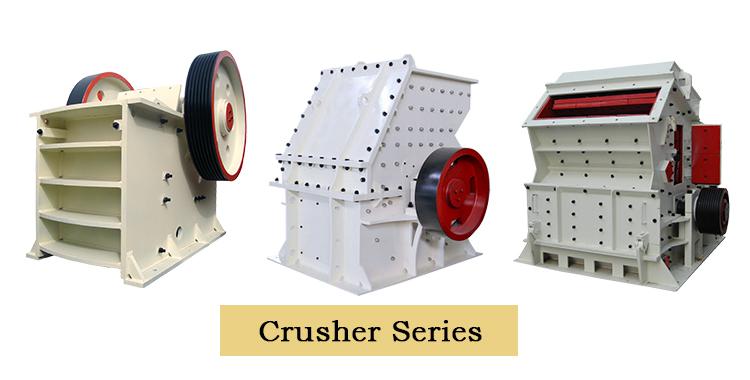

The ore mine can obtain better crushing effect through the jaw crusher. In the subsequent sieving process, the crushed barite ore is very uneven in thickness, and the beneficiation equipment generally has its own selected grain size and selected grain size range, so the broken barite mine passes through the vibrating screen. Screening can optimize the next sorting process. The jigger is mainly used for gravity sorting of barite ore. The jig is selected for large particle size, wide range of selected grades, and has the advantages of large ore dressing, high recovery rate, energy saving, high efficiency and environmental protection. After obtaining high-purity barite, it is necessary to use the grinding process. The barite mill series has a high-pressure mill, a superfine mill, etc., which can process barite into other fields. The fineness greatly expands the application range of barite.

The barite crusher is a crushing device introduced through the continuous research on the physical properties of barite materials. The device can effectively break the barite, which not only prolongs the service life of the equipment, but also can be used once. The crushing of the barite is achieved, which not only improves the output, but also brings great economic benefits to the customer.

In various large-scale engineering construction projects, the application of barite is very extensive, and the barite crusher equipment has also received attention and attention from the industry. As a professional crusher equipment, barite crusher equipment is a very common equipment in the ore market. In all kinds of engineering construction projects, without the help of barite crusher, many ores are unable to be crushed. This shows the importance of the barite crusher.

Barite crusher maintenance:

Strictly follow the production requirements of barite crusher to feed the sanding machine. The feeding amount and feeding particle size must meet the designing process standard, and the cutting should be uniform and continuous. During the normal production operation of the equipment, regular attention should be paid. Observe and record the discharge of the equipment and the operation of the transmission part, pay attention to prevent the blockage of the barite crusher; check the lubrication of the lubrication part regularly, regularly slide the lubricating oil, check the cooler regularly, The working state of the filter; the barite crusher should pay attention to check the oil pressure of the locking cylinder before starting the machine. Before starting, the adjusting ring should be placed in the locking position; the wearing parts of the equipment are recrystallized. The stone crusher expert's suggestion is to check regularly and replace it in time. In particular, it is necessary to observe whether the fastening bolts on the adjusting ring of the lining plate are loose, and tighten the loose bolts in time.

Barite is a non-metallic ore with a glass luster and is usually white or light yellow in color. Barite is widely used in chemical, light industry, building materials, glass and other industrial fields. Barite can be used as a cosolvent for glass production, as a filler for paints, rubber, plastics, etc., with industrial fields. With the rapid development, the prospect of using barite will be more and more broad.

Barite can be used as a white pigment, and can also be used in chemical, paper, textile fillers. It can act as a flux and increase the brightness of glass in glass production, but it is mainly used as a weighting agent in the drilling industry. Refined. In addition, barite can also be applied to zinc antimony pigments, various antimony compounds, filler industries, mineralizers for cement industry, anti-radiation cement, mortar and concrete, road construction and many other fields. The barite and the oil are blended and applied to the cloth base to make the tarpaulin; the barite powder is used to refine the kerosene; the digestive tract contrast agent is used in the pharmaceutical industry; the pesticide, the leather, the fireworks and the like can also be prepared. In addition, barite is also used as an extraction metal crucible for use as a getter and binder for televisions and other vacuum tubes. Barium is alloyed with other metals for bearing manufacturing.

Email: sales@clirik.com

WhatsApp: +8613917147829/+8613512155195

Websites: www.baritegrindingmills.com

www.clirik.com

www.clirikchina.com

评论

发表评论